Behringer has officially released Vintage, its free VST synth plugin (yes, really this time)

The company says it’s worth $99, but you can have it for nothing

The company says it’s worth $99, but you can have it for nothing

You have your pick of overdrive, distortion, delay and flanger in this insane pedal offer from Fender

As well as what appears to be the Brazilian powerhouse, Clown and Tortilla Man seem to have switched to Tama too…

Shake It Off is “all sung one or two notes going up and down,” he says

Vigil Of War guitarist joins the Chicago band after an open audition process that attracted 10,000 applications

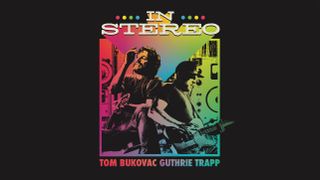

Nashville stringers Tom Bukovac and Guthrie Trapp together on record at last – "We kept a lot of first takes"

For Collen, working with Lange is like “going to school for your favourite subject” but recreating the studio magic live on Def Leppard tracks such as Live Bites can be very tricky at first

As the guitarist and songwriter goes public with his art, he reveals he's also looking to go back and rework some of the band's songs that Lizzy didn't do justice to in the studio

King checked in with Nashville’s Carter Vintage Guitars and got acquainted with a Les Paul with a “literally perfect” faded Iced Tea finish, and turned an acoustic standout track electric

Our expert pick of reliable headphones to suit any type of DJ, including options from Sennheiser, Technics and Pioneer

The IR-D preamp pedal takes those Friedman's high-end amp sounds and puts them in a tube-driven pedal, with dual boosts, onboard IRs, MIDI control and effects loop

"Many years ago, I met Bruce as a wide-eyed 13 year-old," says Jeff Babko. "When his first record was released and exploded on the radio airwaves, I felt as if I’d brushed up against Superman"

Synthesis is one of the quickest and, potentially, easiest methods of creating awesome, original bass sounds. Here’s how it’s done…

Create unique sounds and textures by fusing reverb with other effects

Create your own reverb effects with our step-by-step tutorial

Recreate room acoustics reverb with our step-by-step tutorial

Take our advice, and become a reverb master in no time

While we can manipulate those regular sounding ’verbs with ease, it’s time to explore how to make all manner of reverb-based effects…

Make with the funky drumming in this speedy Live 12 tutorial

This parlour version of Fender’s best-selling beginner acoustic offers big tones in a smaller, more comfortable package

Specialist live music earplugs promise to dampen the sound, but not the magic

IK’s tiny but mighty Tonex One promises all the quality of its bigger brother, shrunk down to mini-pedal format

One of the world’s most popular studio microphones gets back to basics. We find out more

Is this your new best case scenario? We find out

This affordable multi-effects pedal looks to tempt beginner guitar players away from the practice amp with loads of functionality and sounds

This all-in-one room correction package means no more excuses for a muddy low-end

It’s designed for snare drums. It’s a microphone. It’s the Lauten Audio Snare Mic